Think Rene Herse, and you tend to think of plush tubeless tires with big names that bring to mind the mountain passes, verdant rainforests, ribbon roads and rich loam of the Pacific Northwest. However, while Rene Herse has many tubeless tires in its range, the team behind the brand, led by cycling scientist Jan 'All-Road' Heine, frequently ride with tubes, or bring tubes as backup to support their tubeless rigs. Indeed, the brand has a handful of tube-only tires in its range, too, so when we heard that a Rene Herse TPU inner tube was on its way, we weren't surprised, although we did wonder how the Rene Herse model would differ from the other TPU tubes on the market. Luckily, Jan was available for a pre-launch chat. Here's our Q&A.

Hey Jan! To get straight into it: Why tubes when the future seems to point to tubeless?

Thanks, Pete. Ok, so tubeless is great for many applications—whether gravel racing, where you race in a peloton and don't even see the big rocks you hit, or riding on highway shoulders where all those steel wires cause tiny holes that tubeless sealant can seal. But there are drawbacks: You need to top up the sealant frequently, and mounting tires is more challenging. For many riders, tubes are a hassle-free option: Even after not riding a bike for months, you can just inflate the tires and go without worrying whether the tires will hold air.

What is special about these tubes? How do they differ from other tubes? And what is TPU?

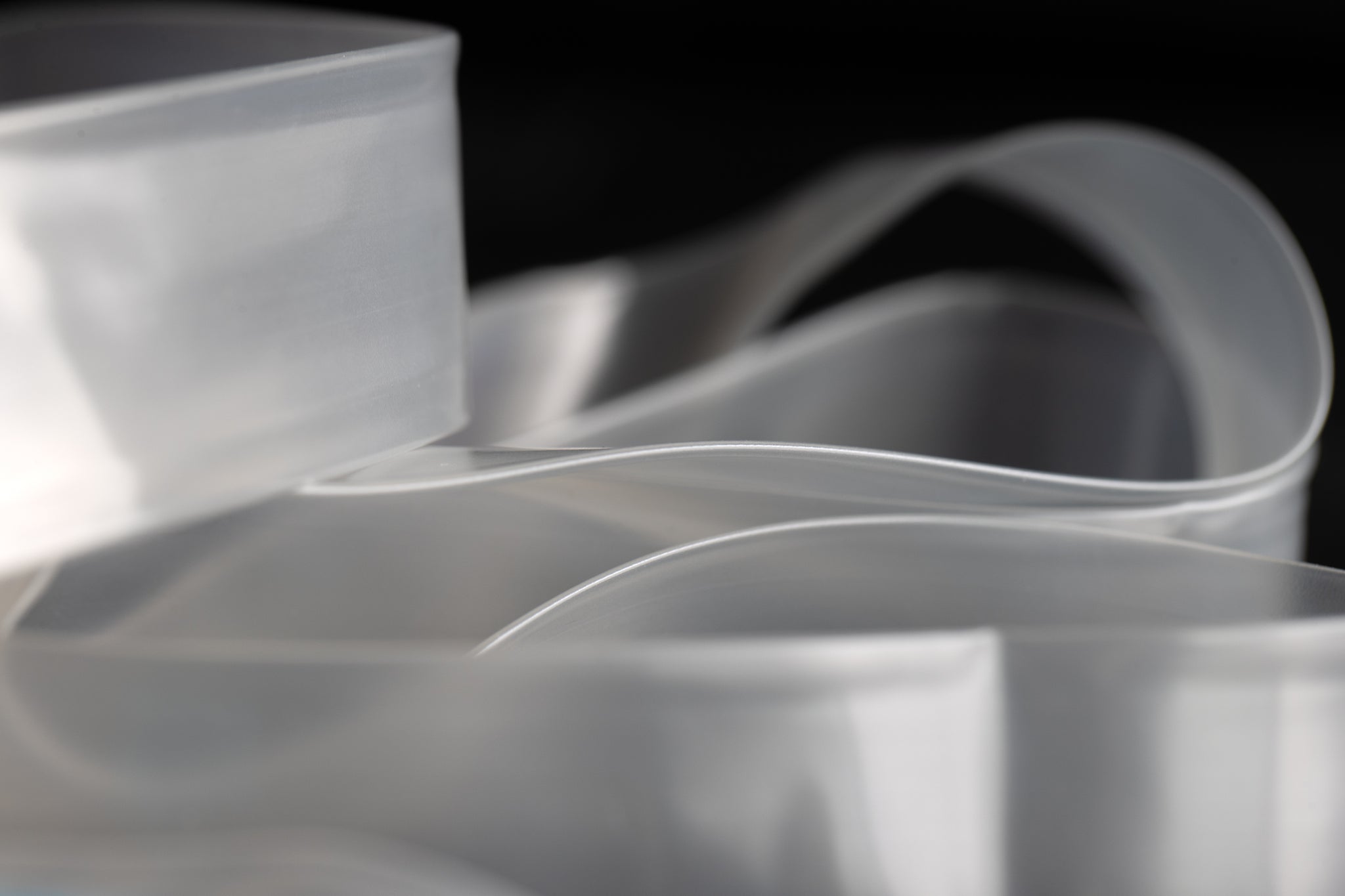

TPU stands for thermoplastic polyurethane. It's an elastomer that can be melt-processed, so you can extrude it into inner tubes. It's far stronger than butyl, the black rubber traditionally used for tubes. You can make it way thinner and lighter than butyl, and yet it's still stronger. And compared to latex—the traditional choice for high-performance tubes—it's not porous, so you don't have to inflate your tires every day.

Another benefit is that TPU tubes roll faster than butyl tubes—and also faster than tubeless, which is slowed down by the liquid sealant sloshing around inside the tire. In fact, TPU tubes roll as fast as latex tubes, are even lighter, and don't leak. So if you’re into the ultimate performance, TPU tubes are the logical choice.

Why did you decide to make the tubes?

We've got a full range of tubeless-ready tires, but we also use tubes on many of our bikes. So we've always been looking for faster and lighter tubes. I ran some ultralight latex tubes in last year's Paris-Brest-Paris 750-mile brevet. Performance and comfort were excellent, but they leaked too much air over the course of the 60-hour ride. I had to start with too much air and still re-inflate after 30 hours on the bike. That's not ideal.

Before we committed to TPU tubes, we wanted to test their rolling resistance on real roads with a rider. We know that lab tests on steel drums can give erroneous results. (For example, the drum tests show that higher pressures roll much faster, but in the real world, they don't.) So, we made some prototypes and tested those in real-road roll-down tests. When we found that they were significantly faster than butyl tubes—in fact as fast as ultralight latex tubes—we decided to proceed with this project.

Where are your tubes made?

Our TPU tubes are made in Germany to our specifications. Since the TPU material is so extremely light, there’s the temptation to go to the absolute limit and create a 27 gram road tube. We didn’t go for that. As with all our products, we make superlight tires and components, but we also demand excellent durability. So we added 6 grams to the tube to make the material a little thicker, which greatly improves resistance to punctures and pinch flats. This also makes it easier to mount the tire on today’s tubeless-ready rims, where the tire suddenly pops into place and can overstretch the tube.

What size tires will they fit?

We offer TPU tubes for road, gravel and mountain bike tires—between 20 and 68 mm wide, in 700C, 650B and 26". The material stretches quite a bit, so you can use the same tubes for a range of sizes.

You use an aluminum valve stem - why is that? Is it removable?

One problem with many TPU tubes is that the valve stems are made from plastic. The valve cores themselves are metal, of course, and when you screw them in, the plastic deforms and tends to leak. We’ve found that many TPU tubes leak, not because the tube material is porous, but because the valves don't seal. The Rene Herse TPU tubes use patented all-metal valves to eliminate that problem. We offer them with 50 mm and 70 mm valve stems. And yes, the valve core is removable.

TPU tubes aren't cheap. What happens if you get a flat?

TPU tubes are remarkably tough. During our testing, I rode mountain bike trails and bottomed out many times without getting a pinch flat. In all our testing, I didn’t get a single puncture from glass or other debris. However, if that happens, patching the tubes is very easy. You use an alcohol wipe to clean the tube, then stick a self-adhesive patch on the hole. There's no need to roughen the tube with sandpaper or use vulcanizing fluid. It takes less than 30 seconds to patch the tube, and it's as good as new. Rene Herse is offering the patch kits to go with the tubes.

What else would you like to share about the new Rene Herse TPU tubes?

The tubes pack so incredibly small that they are ideal as spares, too—even if you’re running tubeless. Together with an ultralight pump like our Rene Herse NUDA, that’s great insurance when your tubeless tire fails to seal after a cut.

Here at Rene Herse, we enjoy most of our rides on empty backroads that don’t have much debris, so flats aren’t an issue. That’s why most of us at Rene Herse like the hassle-free setup and superior speed of these TPU tubes. In fact, I plan to run them at Unbound XL, the big gravel race in the Flint Hills of Kansas, this year.

Back to Journal